Assessing strengths and weaknesses of clients

In management consulting, it is crucial to identify the client's strengths as well as their weaknesses. Many clients provide mixed information or a distorted view about their problems, and the management consultant must filter this information to pinpoint specific challenges. A business that is looking to relocate might assume its old strategies will work in a new market. However, there will be different challenges. The client must understand the information, and the consultant must present suggestions to them in a way that is easy to digest and tailored to their business needs.

Management consultants should not be seen as advocates for one management style. Their work must contribute to the overall efficiency of the organization. They must be able communicate with clients and other departments to address their concerns. The consultant must be able connect issues with the client's larger goals as well as future plans. It is important to lower the barriers to improvement in order for clients and consultants to encourage better management.

Business processes that are efficient

Creating efficiencies in business processes is important to keep a business profitable and competitive. As technology improves, businesses must constantly review and improve their processes to maximize resource utilization, product quality and profits. A Process Efficiency Consultant is able to provide objective analysis of your business processes, and suggest ways to improve them. They will then devise solutions to achieve change.

A business process refers to a sequence of activities that creates a product/service in response to customer demand. To achieve your business goals, it is important to have efficient processes and customers who are happy. Inefficient processes can be costly to maintain, and they will become less efficient as the business grows. If these problems are not addressed, they can quickly become massive.

Business process consultants are a popular choice for many financial institutions. As the public perception of financial institutions changes, these companies will need to adopt secure strategies for growth, increase system resilience and improve regulatory compliance and management of risk and evolve client-facing technology.

Implementing the recommendations

Consulting clients often hire consultants to solve their problems. However, they do not participate in the implementation of the recommendations that were made during the consultation process. The reputation and credibility of a consulting firm is dependent on the quality of its recommendations. It is therefore crucial to follow the recommendations. There are steps consulting firms can take that will increase their chances for success.

First, ensure that your contract includes implementation. It is possible to request an extension. The consulting client may be interested in such an extension, and it can help to strengthen the relationship between the consulting firm and the client. This can help the consultant to ensure that the recommendations are implemented. It also strengthens the client-consultant relationship.

The consulting process should be aimed at reducing the barriers to improvements, which may be preventing the organization from implementing the recommendations. The consultant should not be seen as a crusader. They should instead be a practitioner who is consistent with their views. A consulting process should also encourage experimentation using more effective management styles.

FAQ

How to effectively manage employees

Achieving employee happiness and productivity is key to managing them effectively.

This includes setting clear expectations for their behavior and tracking their performance.

To do this successfully, managers need to set clear goals for themselves and for their teams.

They should communicate clearly with employees. They need to communicate clearly with their staff.

They must also keep track of the activities of their team. These include:

-

What was accomplished?

-

How much work did you put in?

-

Who did it all?

-

Was it done?

-

Why was it done?

This information can be used to monitor performance and evaluate results.

Why is Six Sigma so popular?

Six Sigma is easy to use and can lead to significant improvements. Six Sigma also gives companies a framework for measuring improvement and helps them focus on what is most important.

How does Six Sigma work

Six Sigma uses statistical analyses to locate problems, measure them, analyze root cause, fix problems and learn from the experience.

The first step is identifying the problem.

Next, data is collected and analyzed to identify trends and patterns.

The problem is then rectified.

Finally, data will be reanalyzed to determine if there is an issue.

This continues until the problem has been solved.

What is Six Sigma and how can it help you?

It's an approach to quality improvement that emphasizes customer service and continuous learning. The goal is to eliminate defects by using statistical techniques.

Six Sigma was developed at Motorola in 1986 as part of its efforts to improve manufacturing processes.

This idea quickly spread throughout the industry. Today, many organizations use six sigma methods for product design, production and delivery.

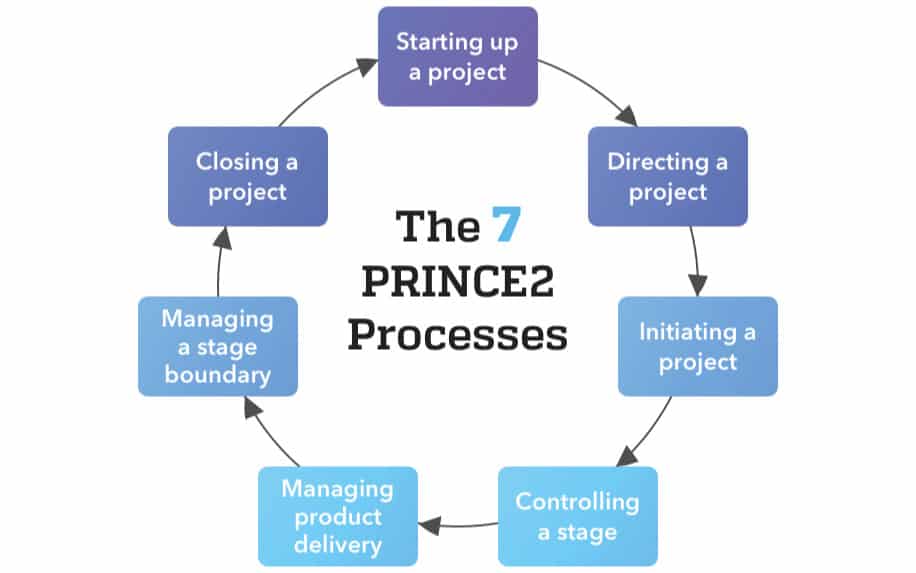

What are the 5 management processes?

Each business has five stages: planning, execution and monitoring.

Planning involves setting goals for the future. It involves setting goals and making plans.

Execution is when you actually execute the plans. You need to make sure they're followed by everyone involved.

Monitoring is checking on progress towards achieving your objectives. Regular reviews of performance against budgets and targets should be part of this process.

Review events take place at each year's end. These reviews allow you to evaluate whether the year was successful. If not, it is possible to make improvements for next year.

Following the annual review, evaluation is done. It helps you identify the successes and failures. It also gives feedback on how well people did.

What are management concepts, you ask?

Management concepts are the fundamental principles and practices that managers use when managing people and their resources. They cover topics like job descriptions (job descriptions), performance evaluations, training programmes, employee motivation and compensation systems.

What is the difference between leadership and management?

Leadership is about inspiring others. Management is about controlling others.

Leaders inspire followers, while managers direct workers.

A leader motivates people and keeps them on task.

A leader develops people; a manager manages people.

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing uses structured methods to reduce waste, increase efficiency and reduce waste. They were created in Japan by Toyota Motor Corporation during the 1980s. It was designed to produce high-quality products at lower prices while maintaining their quality. Lean manufacturing seeks to eliminate unnecessary steps and activities in the production process. It consists of five basic elements: pull systems, continuous improvement, just-in-time, kaizen (continuous change), and 5S. Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement refers to continuously improving existing processes. Just-in time refers to components and materials being delivered right at the place they are needed. Kaizen means continuous improvement, which is achieved by implementing small changes continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. These five elements are combined to give you the best possible results.

Lean Production System

Six key concepts underlie the lean production system.

-

Flow - focus on moving material and information as close to customers as possible;

-

Value stream mapping - Break down each stage in a process into distinct tasks and create an overview of the whole process.

-

Five S's, Sort, Set in Order, Shine. Standardize. and Sustain.

-

Kanban is a visual system that uses visual cues like stickers, colored tape or stickers to keep track and monitor inventory.

-

Theory of constraints - identify bottlenecks in the process and eliminate them using lean tools like kanban boards;

-

Just-in time - Get components and materials delivered right at the point of usage;

-

Continuous improvement: Make incremental improvements to the process instead of overhauling it completely.